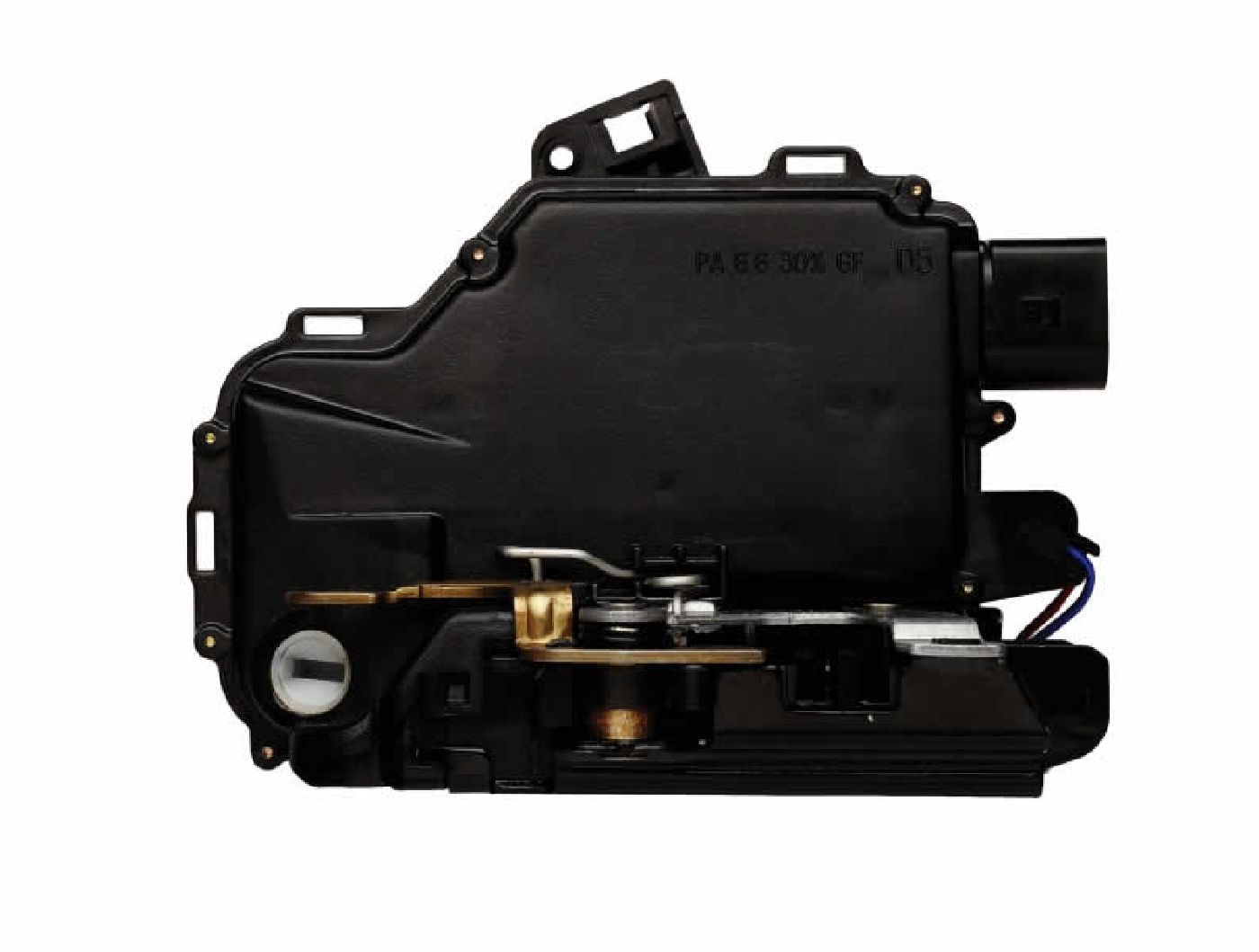

Electromechanically Integrated Vehicle Door Latch

Working alongside the lead designer to ensure that customers requirements were fully met for a common latch design across more than five new vehicles builds including Range Rover, Mini & MGF

Working alongside the lead designer to ensure that customers requirements were fully met for a common latch design across more than five new vehicles builds including Range Rover, Mini & MGF

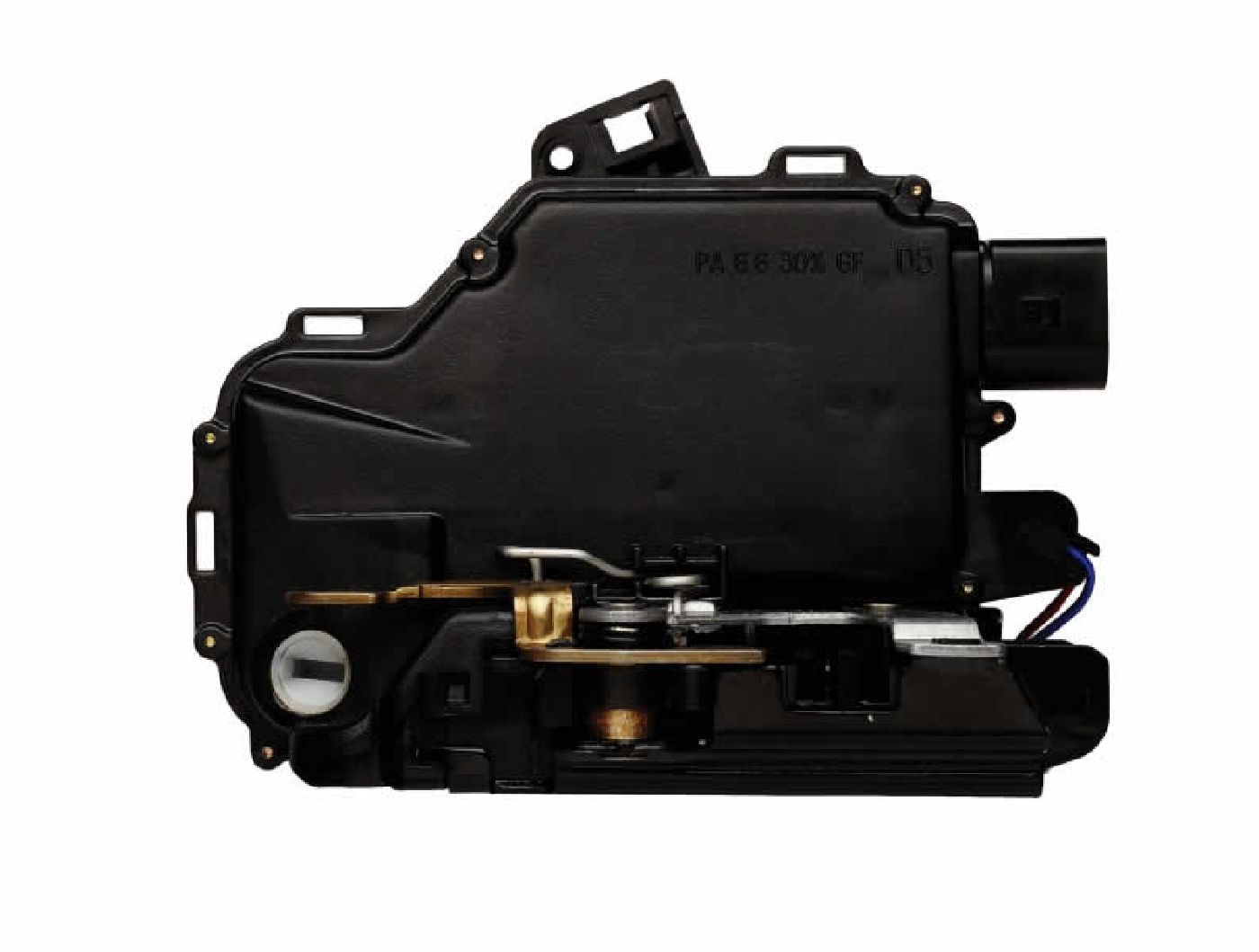

The conventional design method for electrically operated door latches up until this point was the bolt on of external actuators to a conventional latch mechanism. Vehicle logic would be aided by the addition of microswitches to output latch condition. By incorporating all of these features into one assembly it was possible to reduce both tooloing cost and piecepart cost per vehicle.

In order to ensure the design was aligned with the individual needs of each vehicle both in packaging and functionality I liased with the relevent customer sites and build teams.

Also largely involved with vehicle prototype builds and testing, not only inhouse testing but also testing at customers site and independant crash testing at MIRA. From vibration and salt spray to accelerated lifetime and destructive testing to meet comply to customer standards and requirements.