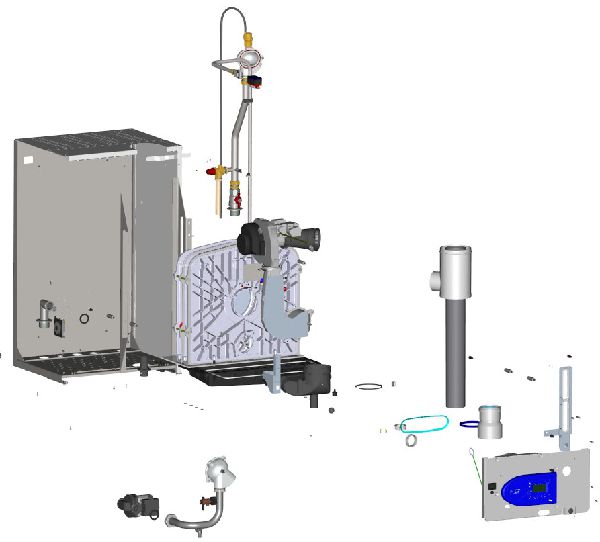

Not only work on the boiler itself but also on the ancillary equipment that is supplied,

The heat exchanger having already been designed gave many process and design challenges. A tight control of datums an mating features enabled the implimentation of this assembly into the finished boiler.

Again not only work on the boiler itself but also on the ancillary equipment that is supplied. Even down to the packaging and transport of the finished product

(Above is a 1.6 Megawatt system)

One of the bigest challenges was to design a sump system that fell within budget and withstand the harsh enviroment. Clever tooling allowed for multiple varients to be accomodated.

You anly have to glance into a boiler to see thecomplexity of parts all of which has to be designed or packaged.

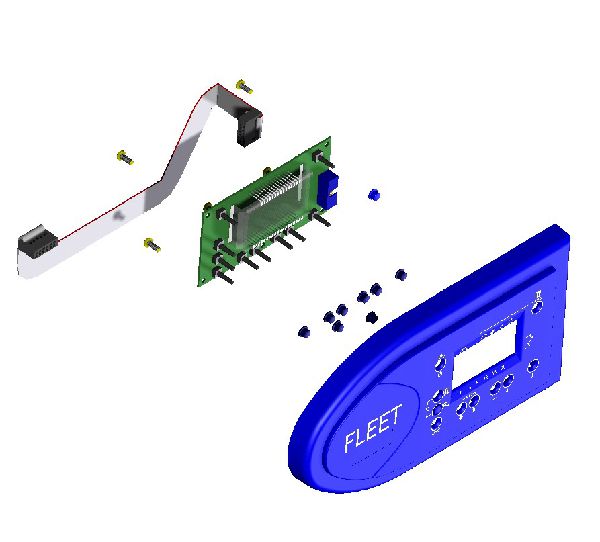

It is always nice to work on anything that has an aesthetic appeal. I worked on this injection moulding together with panelling to give a clean and stylish appearence to the boiler range.